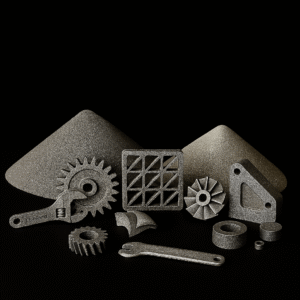

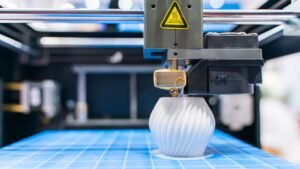

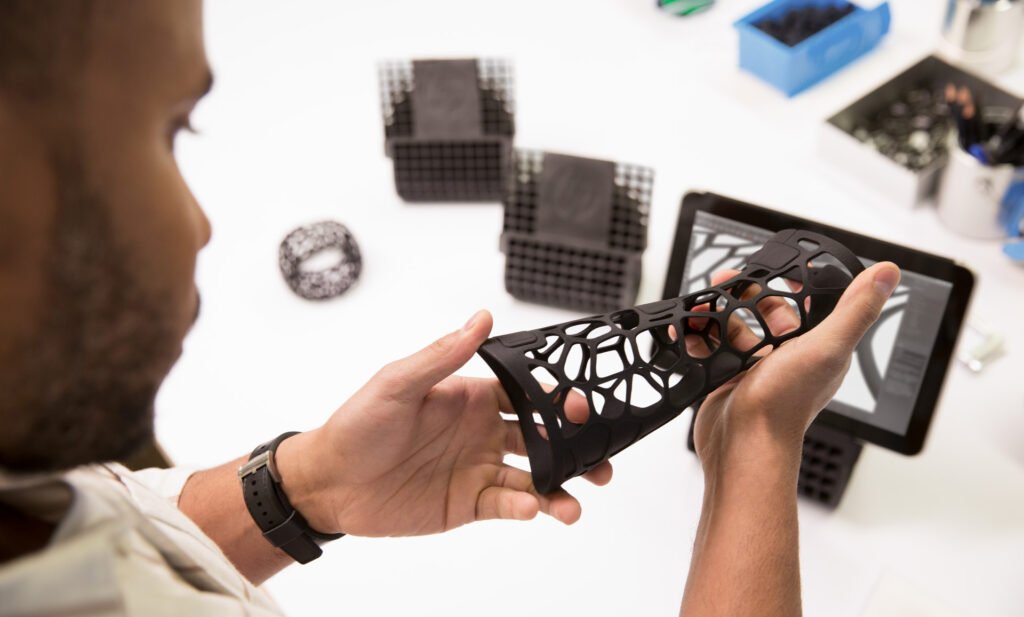

3D prototyping is no longer limited to the design or tech industry — it is now widely used across automotive, aerospace, healthcare, consumer electronics, and many more sectors. This blog explains how each industry benefits from rapid prototyping. For example, automotive companies use it to develop functional parts and fit-test components, while healthcare uses it for surgical guides and custom medical devices. Aerospace companies utilize high-strength materials for testing lightweight components, and consumer brands rely on it for creating aesthetic models and functional prototypes. We also cover how Protofy3D supports different industries with tailored material options, advanced print technologies, and quick turnaround times. Whether you’re a startup or a large enterprise, understanding how 3D prototyping works across industries can help you choose the right approach for your next project.

case studies

See More Case Studies

Why Protofy3D Is the Best Partner for Your Rapid Prototyping Needs

Protofy3D is more than a 3D printing service — it is a complete rapid prototyping partner. This blog gives readers a full inside look at

Can 3D Prototyping Be Used for Production? Here’s the Truth!

Many people believe 3D printing is only for making prototypes, but today’s technology proves otherwise. This blog explores how 3D prototyping has evolved into low-volume

Top 3D Prototyping Trends of 2025: Innovations Shaping the Future

The world of 3D prototyping is evolving rapidly, and 2025 is bringing some exciting innovations that will change the way products are designed and manufactured.