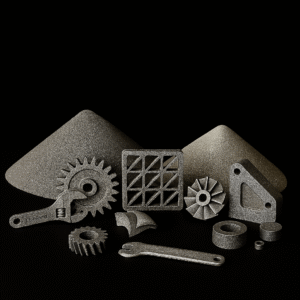

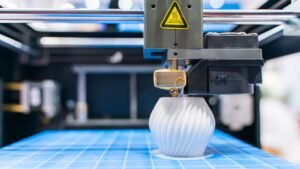

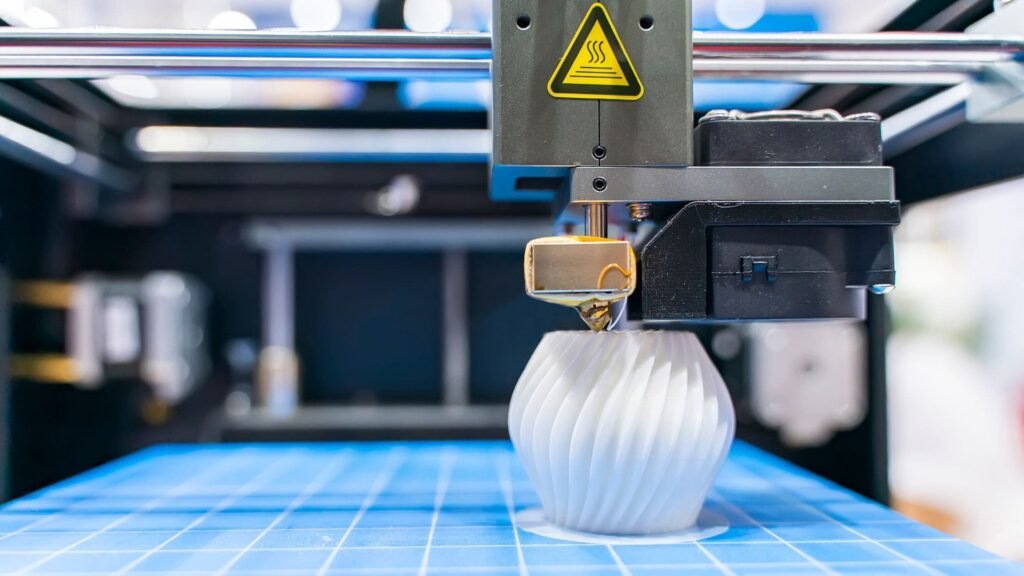

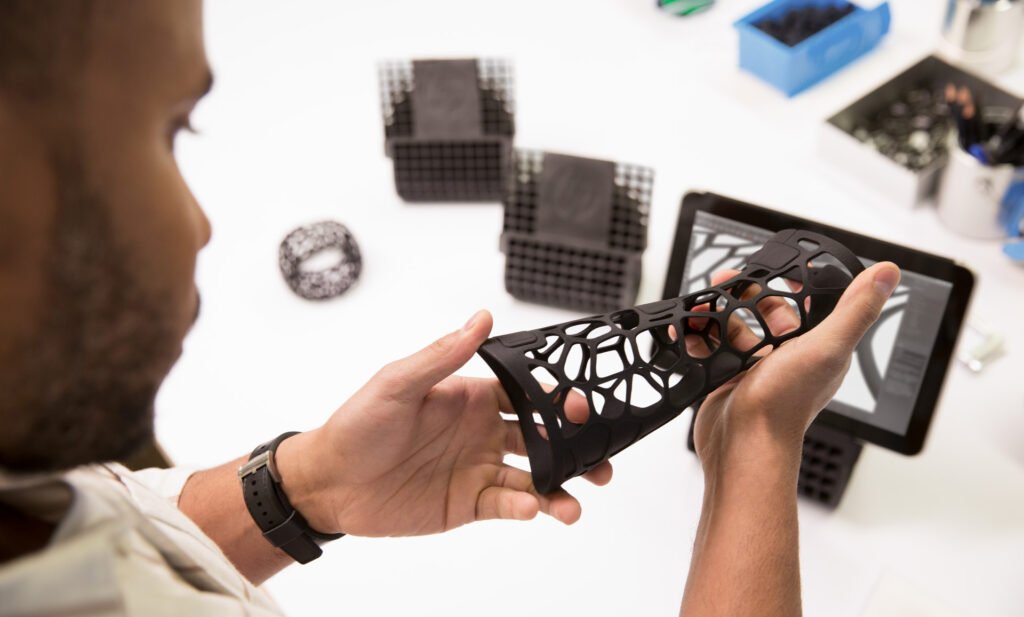

Many people believe 3D printing is only for making prototypes, but today’s technology proves otherwise. This blog explores how 3D prototyping has evolved into low-volume and even mid-volume production for various industries. We discuss how businesses use 3D printing for customized parts, spare components, and end-use products that require speed, precision, and flexibility. The article also covers cost comparison between traditional manufacturing and additive manufacturing, showing when 3D production is a smarter choice. Protofy3D already supports clients with small-batch production, rapid iterations, and high-quality functional parts. Whether you’re looking to launch a pilot batch or need custom components, this blog explains why 3D printing can be a powerful production method for modern businesses.

case studies

See More Case Studies

Why Protofy3D Is the Best Partner for Your Rapid Prototyping Needs

Protofy3D is more than a 3D printing service — it is a complete rapid prototyping partner. This blog gives readers a full inside look at

How Different Industries Are Using 3D Prototyping A Complete Breakdown

3D prototyping is no longer limited to the design or tech industry — it is now widely used across automotive, aerospace, healthcare, consumer electronics, and

Top 3D Prototyping Trends of 2025: Innovations Shaping the Future

The world of 3D prototyping is evolving rapidly, and 2025 is bringing some exciting innovations that will change the way products are designed and manufactured.