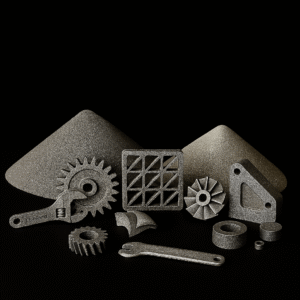

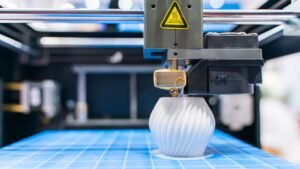

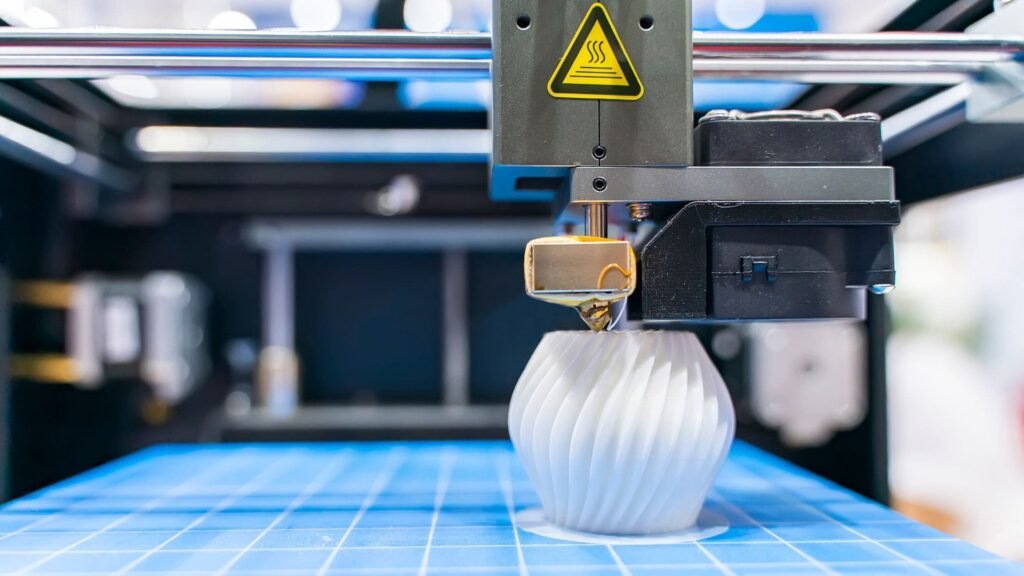

3D prototyping has completely transformed the product development cycle, making it faster, smarter, and more reliable than ever before. In this blog, we explore how a digital CAD model turns into a functional physical prototype within hours — allowing designers and startups to validate ideas at an early stage. We break down each step of the process, including design preparation, material selection, printing method, finishing, and testing. This article also highlights why companies today prefer rapid prototyping over traditional manufacturing. Whether you’re building an electronic device, a mechanical part, or a consumer product, 3D prototyping helps you check design flaws, improve accuracy, and reduce overall development cost. If you’re planning to launch a new product or enhance an existing one, this guide will help you understand how Protofy3D can bring your ideas to life with high precision and speed.

case studies

See More Case Studies

Why Protofy3D Is the Best Partner for Your Rapid Prototyping Needs

Protofy3D is more than a 3D printing service — it is a complete rapid prototyping partner. This blog gives readers a full inside look at

Can 3D Prototyping Be Used for Production? Here’s the Truth!

Many people believe 3D printing is only for making prototypes, but today’s technology proves otherwise. This blog explores how 3D prototyping has evolved into low-volume

How Different Industries Are Using 3D Prototyping A Complete Breakdown

3D prototyping is no longer limited to the design or tech industry — it is now widely used across automotive, aerospace, healthcare, consumer electronics, and